General Safety

Wellness

Cornell recognizes the importance of maintaining a healthy work-life balance and actively supports the health and well-being of all members of the campus community. CLASSE encourages you to give strong attention to wellness of mind, body, and spirit. Your state of wellness can affect your judgment and ability to concentrate, thus affecting your own safety and that of those around you. A surprisingly large fraction of on-the-job injuries occur while walking, reaching, lifting, climbing, or crawling; be aware of your personal limitations and avoid working past them. For more information regarding Cornell's many wellness-related programs, please consult the Cornell University Wellness Program resource page.Awareness & Personal Protection

Pay attention to your surroundings as you move throughout the CLASSE facilities, and adapt your behavior and personal protections accordingly. Areas may not be the same as when you last saw them, and temporary work may restrict passage or maintain a safe perimeter. For example, it is not permitted to enter laboratory areas (labs, high bay areas, shops) without closed-toe shoes (no flip-flops!) and protective apparel appropriate to the space, such as eye protection for a chemistry area or a hardhat if a crane is in use. Watch for signage and listen for warnings and alarms.STOP WORK AUTHORITY

In CLASSE facilities, all personnel have the authority and obligation to stop any activity that appears to pose an immediate safety hazard. Likewise, all personnel in CLASSE facilities must cease their own work if asked to do so for safety reasons. It is also an obligation of anyone stopping work to immediately bring such conditions to the attention of the supervisor(s) of those involved and the Safety Director, and to resume work only after a satisfactory resolution is established.Working Alone

Some of the work areas or the jobs that are done at the Lab have hazards associated with them. For this reason new personnel are not permitted to work alone in the tunnels, shops, laboratories or anywhere with hazards, or after normal working hours anywhere, until they have had a safety orientation and any relevant training for the tasks at hand. Everyone involved in activities that involve substantial hazards must abide by the Two-Person Rule: No operation involving a known risk shall be carried out by any person working alone; risk shall be considered eliminated only after two competent people have agreed to this judgment . Examples of hazardous situations are: using machine shop equipment, working with or near exposed voltages (greater than 50V peak), high-current buswork, or highly corrosive chemicals, moving heavy equipment, and operating a crane when the point of operation is not in full view of the operator (these are only examples; there are many other other hazardous activities).Safety Plan

Many hazardous activities are associated with a specific Safety Plan developed for and by previous researchers, frequently in consultation with experts, and approved after review. You can ask your supervisor if such a plan exists and if there are written procedures associated with it that identify the hazards and how to accomplish tasks safely. (You can search for previous safety plans and procedures among the CLASSE safety documents.) New activities with significantly different hazards than previously encountered, or done in a location significantly different from previous ones, require approval. The Safety Director can provide assistance, as can reference to previous safety plans. Procedures that can be simply described and associated hazards easily mitigated are generally approved directly by the CLASSE Safety Director after review of the submitted Safety Plan. Complex and/or more hazardous activities require full Safety Committee approval; such plans must be presented to the Safety Committee by someone, generally a senior researcher or principal investigator with knowledge of and authority over all aspects of the project. For temporary approval (to last until the next Safety Committee meeting) or for activities of intermediate complexity and hazard, the Safety Director may appoint an ad hoc committee of two or more people to review the Safety Plan. In all cases, researchers are expected to submit a Safety Plan sufficiently prior to commencement of potentially hazardous work in order to allow time for review.Injury/Illness/Exposure Reports

Immediately report any injury, illness, potential hazardous exposure, or "near-miss" incident to your supervisor, who should, generally within 24 hours, file a Cornell EHS online Injury/Illness/Exposure Report. The existence of such an incident report ensures employees that they will be covered through Workers' Compensation for any injury that occurs while at work. Even if an injury seems relatively minor when it occurs, serious complications may develop at a later time. Thus, it is in each employee's best interests that a report is filed soon after the incident occurs. Doing so promptly ensures that details are accurate and that both the employee and the University are protected if any complications arise. Incident reports also help CLASSE and Cornell to identify safety problems and plan for safety improvements. The online report (https://ehs.cornell.edu/campus-health-safety/occupational-health/injuryillness-exposure-reporting) is typically filed by your supervisor, but if for some reason this does not occur, you should complete the form within 24 hours of the incident. This form is indexed by your Cornell NetID and your personal information is filled in automatically. Near the end of the form where you can enter additional people to be notified of your report, please enter the NetID's of your supervisor, the CLASSE Safety Director, Jim Shanks (js583) and the CLASSE Administrator, Katerina Malysheva (evm23). The report can be supplemented with additional information later on, beyond the 24-hour window, if, for example, the medical prognosis or after-effects change with time. If the injured/ill individual does not have a Cornell NetID (e.g. short term visitors), please contact the CLASSE Safety Director or the CLASSE Administrator to find out how to file an incident report.Reproductive Health

Those concerned about reproductive health and related workplace hazards may avail themselves of services and training from EHS. (Services from CLASSE relevant to ionizing radiation and pregnancy can be found here.) EHS offers a individualized assessment of hazards based upon a form, interview, and workplace inspection. Training is available as EHS-3275 Reproductive Hazards.

Short Term Visitor Policy:

Short Term Visitor Safety Policy

This policy sets out safety-related responsibilities of CLASSE personnel hosting short term visitors, contractors, or vendors to the lab, and those of such visitors once they are here.- Applies for any Laboratory visit extending beyond one working day. It does NOT apply to those already trained and vetted as collaborators or CHESS users. It does not apply to Cornell staff from Facilities, EH&S, or C.I.T.

- A CLASSE host should assist each visitor in completing a short online form, after arrival but prior to commencing observation or work. This form gathers identifying information and a confirmation of safety training provided. (Part of this form replaces the paper "CLASSE Guest Agreement", which is no longer required.) For contractors, vendors, Cornellians, or an external committee, the CLASSE host may choose to fill out the online form on behalf of the individual or group.

- A stay of longer than 7 working days involving experimental, shop, or technical spaces or activities requires taking the CLASSE Safety Orientation (and perhaps other training) through arrangement with the Safety Director, preferably prior to arrival on site (clarification: taking the CLASSE Safety Orientation is not required for PSB visitors who do not frequently access laboratory or technical spaces during their stay).

- A CLASSE host must accompany the visitor at all times when first entering laboratory, shop, or technical work areas. This host function may be shared among several individuals or passed from one to another, but the host(s) must be explicitly aware of their role and responsibilities.

- The CLASSE host or contact should instruct the visitor prior to arrival to enter the building through a public reception area and not to enter laboratory or technical areas unescorted . At Wilson Laboratory visitors should check in at the second floor CHESS reception desk.

- A CLASSE host must show the visitor two emergency exit routes from any likely work area, and summarize hazards and relevant procedures local to those areas. In Wilson Laboratory, if likely work areas include areas on the first or second floor, relevant entrances to controlled areas should be pointed out so they can be either avoided entirely or consciously crossed.

- A visitor may only observe unless provided with task-specific training consistent with CLASSE policy on that task and location. Vendors and contractors may work on designated equipment if they are familiar with it or receive appropriate training.

- A radiation badge should be issued if the individual is likely to enter controlled areas over the course of more than one working day, and used for the entirety of the visit; otherwise, a host may sign out a dosimeter and accompany the visitor while inside controlled areas. If work in controlled areas is estimated to exceed 8 hours, the visitor must satisfy one of

- take an in-person training (contact the Safety Director or Safety Manager), or

- take the online CLASSE General Radiation Safety Training through arrangement with the Safety Director, preferably prior to arriving on site.

- if the work is deemed by a CHESS staff member to be CHESS-user-like, take the CHESS User online safety training

- If work is to occur in the CESR tunnel, a CLASSE host should contact one of Facilities Engineer, Safety Director, or Safety Manager to arrange for specialized (online or in-person) training.

- A visitor already briefed on this policy and safety information may be left alone in work areas not requiring additional training if a designated CLASSE host in the building (e.g. an operator) is aware of the visitor, and the visitor understands how to request immediate assistance (designated host) or summon emergency services (911, nearest pushbutton call boxes, fire alarm pulls). If there are imminent safety hazards involved in the visitor's activities, or such hazards are in close proximity, the visitor may not work alone.

- Special considerations apply to any short term visitor under the age of 18. For such individuals, please consult at least one of: CLASSE Administrator, CLASSE Safety Director, CLASSE Safety Manager.

Hazardous Materials

Before you begin any task, consider possible safety hazards of materials involved. Obtain, read and understand the Material Safety Data Sheets (SDS) for any new materials you use, machine, or handle in any way. Binders containing the SDS for chemicals in use are kept in the administrative offices, with a second copy nearer to likely workspaces. Smaller sets are kept in the shop areas and outside the Newman Chem room for convenient access. Be sure to give copies of the SDS to anyone else who will work with the chemical or material. List any additional hazards such as flammable or pressurized gases, large quantities of solvents or other chemicals, lasers, or radioactive sources. Decide what precautions you should take. If there are possible hazards to you or others or if you are unfamiliar with a new material or process, before you begin, you and your supervisor must take your plans to the Safety Director for a review. You may also consult the EHS SDS pages. Sometimes the quickest way to the SDS that you need is a web search for "Equipment Hazards

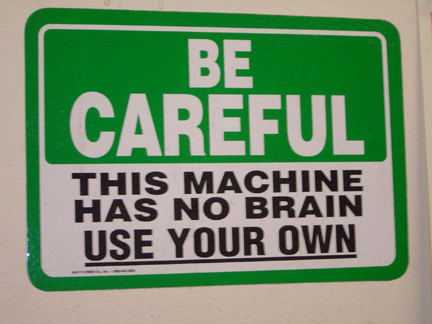

Wilson and Newman Labs are full of machinery and equipment that keep the experiment running. Alertness and preparation are imperative in order to ensure that the equipment remains helpful rather than hazardous. If you work with or around large machinery, be sure you know how to use it and how to avoid its hazards.

Wilson and Newman Labs are full of machinery and equipment that keep the experiment running. Alertness and preparation are imperative in order to ensure that the equipment remains helpful rather than hazardous. If you work with or around large machinery, be sure you know how to use it and how to avoid its hazards. - Forklifts: Forklifts operate on the experimental floors at Newman and Wilson Labs. Stay clear of their paths. You must not operate a forklift unless you have been trained according to OSHA standards (see Safety Training).

- Overhead cranes: Overhead cranes are used to move heavy materials. When cranes are in use, lights flash and bells ring to alert those in the area, but hard hats are still required. Stay clear of overhead loads. Cranes must be operated only by properly trained personnel.

- Consult the EHS Mobile Equipment page

Shop Safety

Before using any machine tool, you must first be given explicit authorization from the Machine Shop Supervisor for that particular shop or piece of equipment. You should make an appointment with the shop supervisor to have one-on-one training. Analyze each job before you begin and consider how you can protect yourself from injury. It is crucial that you pay attention to potential hazards.

The following safety tips apply to both the machine shops and the experimental areas.

Before using any machine tool, you must first be given explicit authorization from the Machine Shop Supervisor for that particular shop or piece of equipment. You should make an appointment with the shop supervisor to have one-on-one training. Analyze each job before you begin and consider how you can protect yourself from injury. It is crucial that you pay attention to potential hazards.

The following safety tips apply to both the machine shops and the experimental areas. - Consult the EHS Tool & Machine Safety pages.

- Eye Safety: You must wear safety glasses when you are in any of the machine shops. Grinding, cutting, and drilling generate particles of metal, wood, lead, and other substances that could cause eye injuries in the absence of appropriate eye protection. You can use the safety glasses located near the shop entrances, or you may obtain a personal set from the stockroom. Check with the business office at Wilson for information about prescription safety glasses.

- Foot Safety: When you regularly work in the experimental areas or shop spaces, you must wear footwear with a protective-toe to protect your feet from being crushed. You may obtain safety shoes and boots from the periodic shoe truck visits, or you may purchase them on your own and be reimbursed (up to a certain amount) through the Wilson business office. Check with your supervisor to see if your job requires that you wear safety shoes. In addition, no open-toed shoes are permitted in experimental or machine shops (e.g. L0, L0E, CESR tunnel, any room in use as a lab).

- Hand Safety: Keep the following tips in mind in order to avoid hand injuries:

- Remove watches, rings, and bracelets before you start to work, especially if you work with moving machinery

- Use gloves that are job-rated for the kind of work you do

- Follow lockout/tagout procedures when cleaning, inspecting, or repairing machinery

- Check tools and equipment for excess wear and dull cutting blades before using them

- Do not ignore safety guards, which are on machines to protect you

- Be aware of doorways and narrow spaces when you carry objects or push them with a handcart. Keep your hands where they can not get crushed

- Keep your hands on the sides of objects when stacking them, not underneath, to avoid crushing your fingers

- Use the right tool for the job, and be sure to use it correctly

- Clothing: hair and clothing can be snagged or grabbed by machinery, especially those with moving parts

- Tie back long hair away from your face; hair still hanging below the collar must be tucked into a cap or hairnet if near moving parts

- Remove neckties or other dangling clothing

- Roll up long sleeves

- Wear a safety apron to protect your body from flying particles of metal or wood

Other Hazards

Other potential hazards include the following:- Back Safety: Before attempting to lift a heavy object, assess how to do so safely:

- Is there a way to reduce weight or reconfigure the object(s) with handles?

- Is the weight more than you can usually lift safely?

- Is there a crane or other assisting device appropriate to the task?

- Is there a safe way to share the lifting with another worker? Do not hesitate to ask your supervisor for a recommendation

- Utilize lifting techniques that place minimum stress on the lower back

- Use the OSHA Back Disorders website as a resource

- Musculoskeletal injuries: Proper workplace ergonomics can prevent such injuries, and Cornell has a free prevention program.

- Unexpected events or emergencies: see Emergency Response

End of General Safety

Copyright © by the contributing authors. All material on this collaboration platform is the property of the contributing authors.

Copyright © by the contributing authors. All material on this collaboration platform is the property of the contributing authors. Ideas, requests, problems regarding CLASSE Wiki? Send feedback