You are here: CLASSE Wiki>CHESS Web>CHESS>OpsDocs>SOP-OPS-011 (30 Aug 2017, ljs30)Edit Attach

| Cornell High Energy Synchrotron Source | ||||

| Doc#: SOP-OPS-011 | Procedure: CHESS Cryostream Setup and Removal | Prepared by: ZB | ||

| Rev.: 3 | Revision Date: 04/14/14 |

Date Effective: 04/14/14 |

Date Expires: 04/14/15 | Approved by: KM |

To prepare the CHESS cryostream for station use.

Materials and Equipment Needed

- Cryostream Cart containing:

- Cold head

- Cryostream Gas Pump

- Liquid Level Controller

- Cyrostream Controller

- Gas regulator

- LN2 Dewar

- Liquid Nitrogen supply and hose

- Eye protection

- Cryogen gloves

- Nitrogen gas supply

- Control Laptop

- CryoPad Software

- Serial to USB adapter

- High pressure gas and cryogenics: Wear face shield and gloves

- High pressure gas and cryogenics: Do not leave any hoses or volumes closed without venting

Setting Up and Starting the Cryostream

- Transport cart and dewar to CHESS Liquid Nitrogen filling station.

- Connect one end of liquid nitrogen hose adapter to dewar fill feedthrough. (Figure 2)

- If fittings are not compatible, remove the KF clamp from the dewar, take the top off, and put the LN2 filling hose directly into the dewar.

- Connect opposite end of hose adapter to Liquid Nitrogen filling station.

- Fill the dewar:

- Open filling station valve slightly until valve and hose are frosted.

- Open valve completely until dewar is full.

- Loosen fittings, remove liquid nitrogen hose adapter and set aside on cart.

- Move cart into position for experiment.

- NOTE: dewar may be placed separate from cart for experiment depending on setup.

- Remove wingnuts on coldhead mount to move cold head from cart. (Figure 3)

- Mount coldhead to optical table near sample using bolts and hole-pattern on table.

- NOTE: Further fine adjustments may need to be made by user once sample is in place.

- Plug cart power strip in to wall outlet.

- Connect gas line from regulator to nitrogen gas supply. (Figure 4)

- Verify that flow is 7 l/min at output. (Figure 5)

- Connect BNC from J5 on rear of Liquid Level Controller to BNC output on top of dewar. (Figure 6)

- Flip power strip switch to turn power on.

- Flip power switch on front of Liquid Level Controller to turn unit on. (Figure 7)

- Verify that Fill Toggle Switch is set to CLOSED. (Figure 7)

- LO alarm should be set to about 7

- To see what value each setting is set to, turn the nob to that setting and flick the Raise/Lower Toggle up quickly. To change a setting, hold the Raise/Lower Toggle up or down to raise or lower a setting.

- Hi alarm should be set to about 19

- NOTE: Values for Hi, A, and B are not very important; they are used for an auto-fill system, which the CHESS cryostream does not use. Values have been entered into the settings to keep the controller functioning.

- Press power switch on rear of Cyrostream Controller to turn unit on.

- TEMP should show ~300K. (Figure 7)

- STATUS should say Cool to: 100.0K. (Figure 7)

- Plug DB9 end of Serial to USB Adapter into SERIAL port on rear of Cyrostream Controller.

- Plug USB end of Adapter into Control Laptop USB Port.

- Start Control Laptop.

- Login:

- username: specuser

- password: CThrooMe

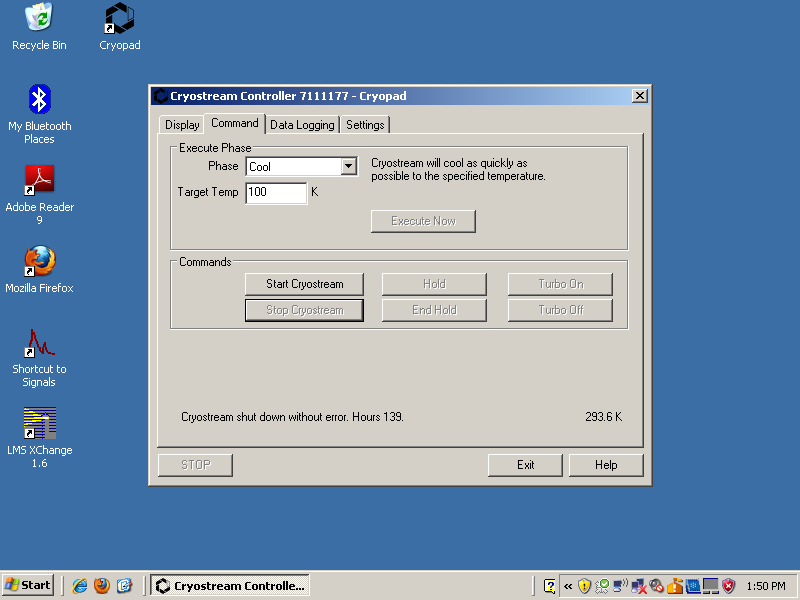

- Double-click on Cryopad icon to start Cryostream software.

- Test Communications:

- Select Command tab. (Figure 8)

- Phase: Cool

- Target Temp 100K

- Press [Execute Now] button.

- Pump Controller and Pump should activate and system should start cooling to 100K.

- Select Command tab. (Figure 8)

- The system takes about 30 minutes to reach its normal operating values. All of the indicators on the display in Cryopad will appear green when it is ready for use, and the Sample Temp will read 100.0K (or whatever temperature the target temp was set to).

The Cryostream should be warmed up to room temperature (~300K) before turning the system off.

- Type 300 in the target temp box; press the [Execute Now] button.

- Once system reaches 300K, controllers can be powered off.

- Power laptop off and disconnect serial cable

- Unplug power strip on cryo cart from wall

- Disconnect red gas line from nitrogen supply

- Remove cryostream head from table (if mounted on table) and place in holder on cryostream cart. Tighten bolts on holder enough so that the cryostream head does not fall out.

- Place dewar on cryostream cart (if it was removed from cart)

- Park cart in G-line hallway

The cryostream controller will give an audible alarm when the liquid nitrogen level reaches the Lo level. To fill the dewar while in a hutch:

- Fill a large LN2 dewar from the LN2 filling station

- See SOP-OPS-010 for instructions on filling the large LN2 dewar

- Roll the large dewar into the hutch

- Connect a hose from the "liquid" valve on the large dewar to the threaded fitting on the cryostream dewar

- If compatible fittings cannot be found, the KF clamp may be removed from the the cryostream dewar and the hose from the large dewar can be stuck into the small dewar. Hold the hose in place (wearing cryo gloves and eye protection) so it does not fall out while filling.

- Open the "liquid" valve on the large dewar.

- The digital display on the cryostream controller will show the level as the dewar is filled. The dewar is full around 19, or when liquid nitrogen starts spilling out of it.

- Close the valve when the cryostream dewar is full.

- Disconnect the hose from the cryostream dewar and remove the large dewar from the hutch.

Figure 1 - Cyrostream Cart

Figure 2 - LN2 Hose Adapter – Feedthrough End

Figure 3 - Coldhead Mounting

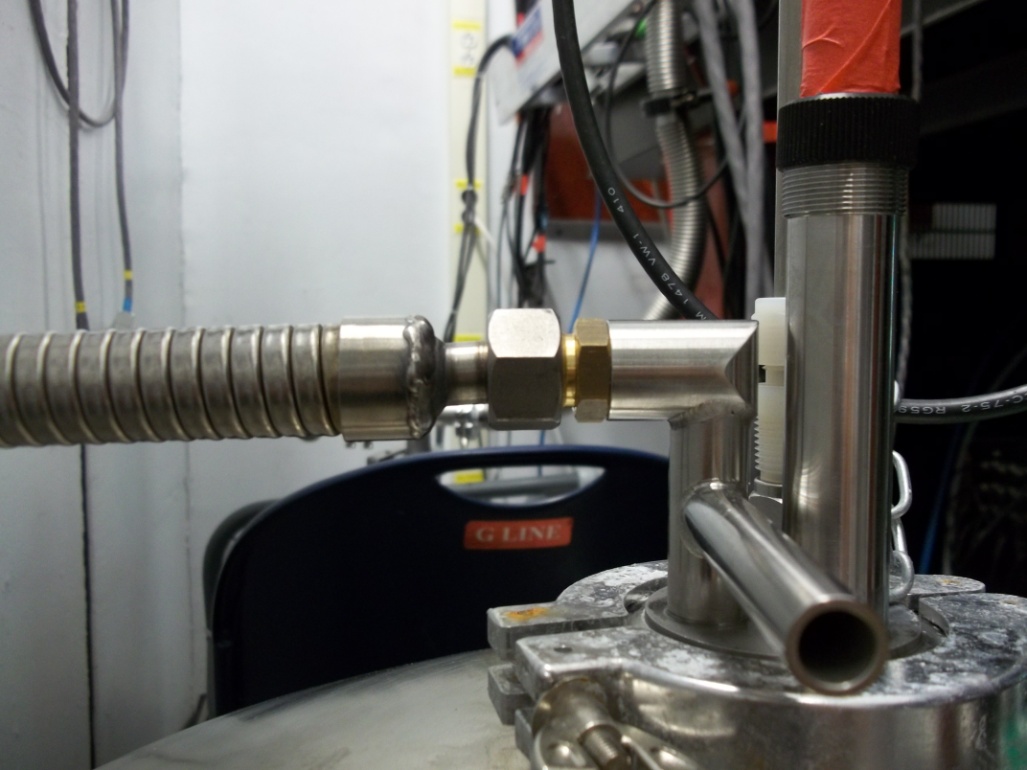

Figure 4 - Gas Connection

Figure 5 - Cryostream Gas Flow

Figure 6 - Cryostream Controller Connections

a) Power b) Fill Toggle c) Set points

Figure 7 - Cryostream Controller Settings

a) Power b) Fill Toggle c) Set points

Figure 7 - Cryostream Controller Settings

Figure 8 - Cryopad Software

References

SOP-OPS-010 - Filling large LN2 dewars

Revision History

Rev. 1 – Initial document (06/20/13 - ZB)

Rev. 2 - Added reference section. Added instructions for refilling the dewar. Added more detail about hi/lo settings (03/14/14 - KM)

Rev. 3 – Made separate section and added details for turning off and disconnecting cryostream (4/14/14 KM) -- LeeShelp - 30 Aug 2017

Edit | Attach | Print version | History: r1 | Backlinks | View wiki text | Edit wiki text | More topic actions

Topic revision: r1 - 30 Aug 2017, ljs30

Copyright © by the contributing authors. All material on this collaboration platform is the property of the contributing authors.

Copyright © by the contributing authors. All material on this collaboration platform is the property of the contributing authors. Ideas, requests, problems regarding CLASSE Wiki? Send feedback